In the ever-evolving landscape of gas detection technology, NH3 TDLAS (Ammonia Tunable Diode Laser Absorption Spectroscopy) emerges as a beacon of innovation. With its precision, reliability, and versatility, NH3 TDLAS gas analyzers are revolutionizing the way industries monitor and manage ammonia gas emissions. In this comprehensive guide, we delve into the intricacies of NH3 TDLAS technology, exploring its workings, advantages, and future implications.

Understanding NH3 TDLAS Technology

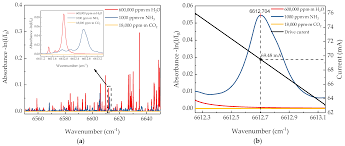

NH3 TDLAS technology operates on the principle of laser absorption spectroscopy, a technique that utilizes laser light to measure the concentration of gas molecules in a sample. Specifically designed for the detection of ammonia (NH3) gas, TDLAS analyzers emit laser light at a specific wavelength that corresponds to the absorption line of NH3 molecules. As the laser light passes through the gas sample, NH3 molecules absorb energy at the resonant wavelength, leading to a reduction in the transmitted light intensity. By analyzing the extent of this absorption, NH3 TDLAS analyzers can accurately quantify the concentration of ammonia in the sample.

This advanced technology offers several advantages over traditional methods of ammonia detection. Firstly, NH3 TDLAS analyzers provide highly accurate and precise measurements, even at low concentrations, making them suitable for a wide range of applications, including environmental monitoring, industrial processes, and agricultural operations. Additionally, NH3 TDLAS technology offers real-time monitoring capabilities, allowing for rapid detection of ammonia leaks or emissions and enabling prompt corrective action to be taken. Furthermore, NH3 TDLAS analyzers are non-invasive and non-destructive, making them ideal for continuous monitoring applications where sample integrity is essential.

Moreover, NH3 TDLAS technology offers enhanced sensitivity and selectivity compared to other ammonia detection methods, allowing for reliable detection and measurement of NH3 in complex gas mixtures. This capability is particularly valuable in industries such as semiconductor manufacturing, where precise control of ammonia concentrations is critical for ensuring product quality and process efficiency. Additionally, NH3 TDLAS analyzers can be integrated into automated monitoring systems, enabling seamless integration with existing process control infrastructure and facilitating remote monitoring and data analysis.

Advantages of NH3 TDLAS Gas Analyzers

NH3 TDLAS gas analyzers offer a myriad of advantages over traditional gas detection methods:

- High Sensitivity: NH3 TDLAS technology boasts exceptional sensitivity, enabling the detection of trace levels of ammonia gas with unparalleled precision.

- Selectivity: The specificity of NH3 TDLAS analyzers ensures minimal interference from other gases, allowing for reliable and accurate measurements even in complex industrial environments.

- Real-time Monitoring: With rapid response times and continuous monitoring capabilities, NH3 TDLAS analyzers provide real-time insights into ammonia gas concentrations, facilitating proactive decision-making and prompt intervention in case of deviations from permissible levels.

- Non-invasive Measurement: Unlike conventional sampling techniques that may require physical contact with the gas sample, NH3 TDLAS analyzers offer non-invasive measurement, minimizing the risk of contamination and ensuring operator safety.

- Wide Range of Applications: From agricultural settings, where NH3 emissions from livestock operations are a concern, to industrial facilities, such as chemical plants and wastewater treatment plants, NH3 TDLAS technology finds diverse applications across various sectors.

The Future Implications of NH3 TDLAS Technology

As the demand for stringent environmental regulations and workplace safety standards continues to grow, NH3 TDLAS technology is poised to play a pivotal role in shaping the future of gas detection. With ongoing advancements in laser technology, sensor design, and data analytics, NH3 TDLAS analyzers are becoming increasingly robust, reliable, and cost-effective.

Moreover, the integration of NH3 TDLAS analyzers with IoT (Internet of Things) platforms and cloud-based monitoring systems opens up new possibilities for remote monitoring, predictive maintenance, and data-driven decision-making. By harnessing the power of connectivity and data analytics, industries can optimize their operations, minimize environmental impact, and ensure compliance with regulatory requirements.

Furthermore, the scalability of NH3 TDLAS technology allows for customized solutions tailored to specific industry needs. Whether it’s monitoring ammonia emissions in agriculture, detecting leaks in industrial processes, or ensuring workplace safety in confined spaces, NH3 TDLAS analyzers offer versatile solutions that address a wide range of applications.

Conclusion

In conclusion, NH3 TDLAS technology represents the future of gas detection, offering unparalleled accuracy, sensitivity, and reliability in measuring ammonia gas concentrations. With its myriad of advantages and future implications, NH3 TDLAS analyzers are poised to transform the way industries monitor and manage gas emissions. As we continue to embrace innovation and harness the power of technology, NH3 TDLAS technology will undoubtedly play a central role in shaping a safer, more sustainable future for all. Its potential to drive advancements in emission management, environmental monitoring, and industrial processes underscores its significance as a catalyst for positive change in the pursuit of cleaner and greener industrial practices.