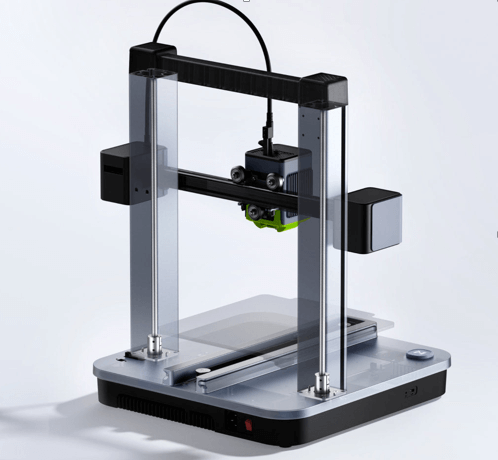

The evolution of 3D printing represents a remarkable transformation in manufacturing technology. Originating as a specialized tool for prototyping, it has evolved into a dominant force reshaping the manufacturing landscape. Key materials, precision, and scalability advancements have propelled 3D printing from a futuristic concept to an essential component of contemporary production processes. This journey signifies a pivotal shift in conceptualizing and approaching manufacturing challenges. The once-niche application of 3D printing for prototyping has become an integral and mainstream force, influencing industries across the spectrum. In its progression, 3D printing has transcended its initial limitations, emerging as a dynamic and indispensable tool in the modern manufacturing toolkit.

Prototyping Pioneers

The inception of 3D printing finds its roots in the 1980s, credited to Chuck Hull, often hailed as the father of 3D printing, who introduced the revolutionary concept of stereolithography. This pioneering technique marked a paradigm shift by facilitating the layer-by-layer creation of three-dimensional objects, all guided by digital models. In its early stages, 3d printer was primarily used in prototyping, offering designers and engineers a swift transition from digital concepts to tangible models. The capacity of this technology to expedite the iteration of designs brought about a seismic change in product development, propelling innovation across diverse industries. The rapid and iterative nature of 3D printing transformed the manufacturing landscape and served as a catalyst, accelerating the pace at which enterprises could bring novel ideas to fruition. Chuck Hull’s groundbreaking invention laid the foundation for a technological evolution extending far beyond its initial prototyping applications, shaping how we conceptualize and realize three-dimensional objects. The legacy of stereolithography endures in the widespread adoption and continuous advancement of 3D printing technologies today.

Materials Matter

As 3D printing gained momentum in prototyping, a notable constraint surfaced in the limited array of available materials. Initially, the technology predominantly focused on plastics, restricting the versatility of 3D printing applications. However, a significant and transformative evolution has transpired in diversifying materials compatible with 3D printers. This progression extends beyond plastics to encompass a broad spectrum, including metals, ceramics, and biocompatible materials. The expansive palette of materials has revolutionized the landscape, creating functional end-use parts with unprecedented flexibility. This transformative expansion of material possibilities has proven to be a game-changer, unlocking myriad applications for 3D printing. Industries such as aerospace now benefit from the utilization of diverse materials, as do medical fields with the production of precise implants and the consumer market through the customization of products.

Mainstream Manufacturing Integration

While 3D printing initially found its niche in prototyping, its journey to mainstream manufacturing was marked by the development of larger, faster, and more precise printers. The advent of industrial 3D printing machines capable of handling complex geometries and producing components at scale paved the way for widespread adoption in manufacturing. Companies across various sectors began integrating 3D printing into their production processes to achieve unparalleled efficiency and flexibility. The technology’s ability to reduce waste, minimize lead times and customize products on demand positioned it as a disruptive force in traditional manufacturing.

Conclusion

What started as a novel method for creating prototypes has evolved into a versatile and indispensable tool capable of producing end-use parts with precision and efficiency. The continuous refinement of materials and the development of sophisticated 3D printing technologies have propelled the industry forward, enabling its integration into diverse sectors such as healthcare, aerospace, and automotive.

The journey of 3D printing reflects a broader trend in the evolution of manufacturing technologies. The once futuristic concept has become a present-day reality, with implications that reach far beyond the confines of traditional manufacturing. As innovations in 3D printing persist, we can anticipate even more profound changes in how products are conceived and brought to life, reaffirming its status as a transformative force in the manufacturing world.