The combination of rapid prototyping and injection moulding gives businesses a comprehensive solution for optimizing their production methods. By leveraging the blessings of speedy prototyping during the design and development degrees, organizations can quickly validate their concepts, perceive layout flaws, and make necessary adjustments before investing in luxurious mass production. This iterative method minimizes the chance of launching a fallacious product and reduces the time of injection molding supplier and resources required for product revisions.

Exploring the perks of injection molding

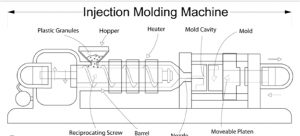

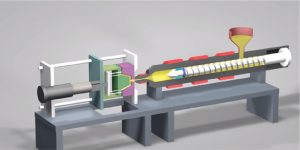

Injection molding is a broadly used production procedure that offers several advantages for businesses seeking to streamline their manufacturing. By injecting molten material, generally plastic, right into a mold hollow space, this technique lets in for the efficient and specific manufacturing of complicated and unique parts.

One of the huge benefits of injection molding is its price effectiveness. The preliminary tooling prices may be higher in comparison to different manufacturing techniques, but once the mildew is created, the price in keeping with the component appreciably decreases.

This makes it perfect for huge-scale manufacturing, as the consistent with-unit fee decreases as the amount increases. Additionally, the excessive manufacturing speed of injection molding allows manufacturers to supply a large volume of parts in a relatively short quantity of time, resulting in better output and quicker turnaround instances.

Improved collaboration and communication

One of the key advantages of implementing rapid prototyping and injection molding tactics is the development of collaboration and communique among crew contributors.

Traditional manufacturing methods frequently involve prolonged and complicated conversation channels, with one-of-a-kind teams and departments working in silos. This can cause miscommunication, delays, and errors within the production system.

With speedy prototyping and injection molding, the entire manufacturing workflow turns into greater streamlined and efficient.

The use of 3D printing generation lets in for the quick creation of bodily prototypes, which may be effortlessly shared amongst crew members for comments and evaluation. This enables higher collaboration and guarantees that everyone is on an equal web page during the improvement method.

Versatility in material selection

Versatility in material selection is a prime gain of making use of speedy prototyping and injection molding within the production technique. These techniques provide an extensive variety of cloth alternatives to pick from, catering to the precise needs and requirements of different merchandise.

With rapid prototyping, diverse substances such as plastic, steel, rubber, or even ceramics can be used to create prototypes. This lets producers test the functionality, aesthetic enchantment, and durability of their designs through the use of special materials, helping them make informed selections before transferring forward with mass production.

Whether it’s a rigid plastic prototype for a customer product or a flexible rubber prototype for a medical device, rapid prototyping gives the flexibility to experiment with distinct substances and discover the first-class suit for the very last product.

Injection molding takes cloth versatility to the next stage. It permits the production of components through the use of a huge variety of substances, inclusive of thermoplastics, thermosetting plastics, elastomers, and even biodegradable substances.

In this manner that manufacturers can choose the most suitable material for their product based on elements that include electricity, flexibility, temperature resistance, chemical resistance, and extra.

From lightweight and impact-resistant plastics for patron electronics to heat-resistant and flame-retardant materials for automotive additives, injection molding gives the capacity to pick from a plethora of materials to satisfy specific performance requirements.