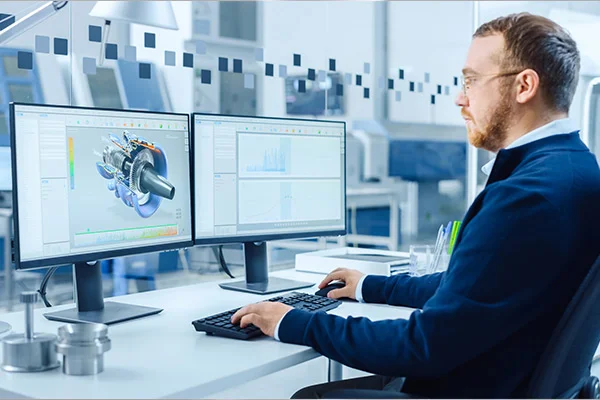

In today’s fast-paced industrial landscape, ensuring product quality is paramount. As industries evolve, so do the demands for quality assurance. Vision systems for quality inspection have emerged as a game-changing technology, offering unparalleled accuracy and efficiency. For those considering adopting such advanced systems, Sciotex stands as a beacon of expertise and innovation in this field.

What Are Vision Systems for Quality Inspection?

Vision systems, at their core, utilize advanced cameras and software to inspect and analyze products or components. These systems can identify defects, measure dimensions, and even verify product assembly. With the integration of artificial intelligence and machine learning, modern vision systems have become increasingly adept at recognizing complex patterns and variations, ensuring consistent quality.

Why Choose Sciotex for Your Vision System Needs?

With over 30 years of experience, Sciotex has cemented its position as a leading Vision System Integrator. Their legacy of success is built on expertly supporting some of the world’s most innovative companies with cutting-edge Vision Inspection Systems. But what sets Sciotex apart?

- Expertise: Sciotex’s team of engineers possesses deep knowledge and expertise in vision system integration. They understand the unique challenges faced by different industries and tailor solutions to meet specific requirements.

- Innovation: Staying ahead of the curve is crucial in the world of vision systems. Sciotex is committed to continuous innovation, ensuring that their clients benefit from the latest advancements in technology.

- Customer-centric Approach: Sciotex values long-term partnerships. Their dedication to client success is evident in their approach to understanding each client’s unique needs and providing tailored solutions that drive results.

Benefits of Vision Systems for Quality Inspection

Implementing a vision system for quality inspection offers a multitude of benefits:

- Enhanced Accuracy: Vision systems can detect defects and anomalies that may go unnoticed by human inspectors, ensuring that only products meeting quality standards reach the market.

- Increased Efficiency: Automated inspection processes significantly reduce the time and resources required for quality control, leading to faster production cycles and lower costs.

- Data-driven Insights: Vision systems generate valuable data that can be analyzed to identify trends, optimize processes, and make informed decisions, driving continuous improvement.

- Flexibility: Vision systems can be easily adapted to inspect a wide range of products and components, making them a versatile solution for diverse industries.

Digital Transformation with Sciotex

At Sciotex, digital transformation is more than just a buzzword. For over 25 years, they have been at the forefront of developing new technologies that improve industrial and scientific operations. Their focus on building resilient, high-performance systems resonates with their commitment to being their clients’ long-term technical innovation partner.

By partnering with Sciotex, you’re not just investing in a vision system; you’re investing in a future where quality assurance is seamless, efficient, and precise. Their team of dedicated engineers will work closely with you to understand your needs, design a tailored solution, and ensure smooth implementation and ongoing support.

Conclusion

Vision systems for quality inspection represent the future of quality assurance in manufacturing and beyond. With Sciotex’s decades of experience and unwavering commitment to innovation and customer success, you can trust that you’re making the right choice for your vision system needs.

Thinking about a vision system? Contact Sciotex today, and let their team of experts guide you on the right path to enhancing quality, efficiency, and profitability.