A transformative technology has surfaced in maintenance and restoration, marking a significant shift towards sustainability and efficiency. This innovation, known as laser rust removal, employs highly focused laser beams to meticulously remove rust and other surface contaminants from metal objects. This advanced method redefines environmental friendliness, safety, and operational efficiency standards in maintaining metal assets, ranging from invaluable historical artifacts to indispensable industrial equipment.

The Enduring Battle Against Corrosion

Traditionally, the fight against rust has been a formidable challenge, involving labor-intensive, time-consuming, and often environmentally detrimental methods. Standard techniques like sandblasting, chemical stripping, and manual scraping require a significant workforce and can harm the environment and the workers’ health. Disposing of chemical waste and abrasive materials in these processes poses a severe environmental hazard. At the same time, the health risks associated with exposure to toxic substances and delicate particulate matter cannot be overstated.

A Green Revolution with Laser for Rust Removal

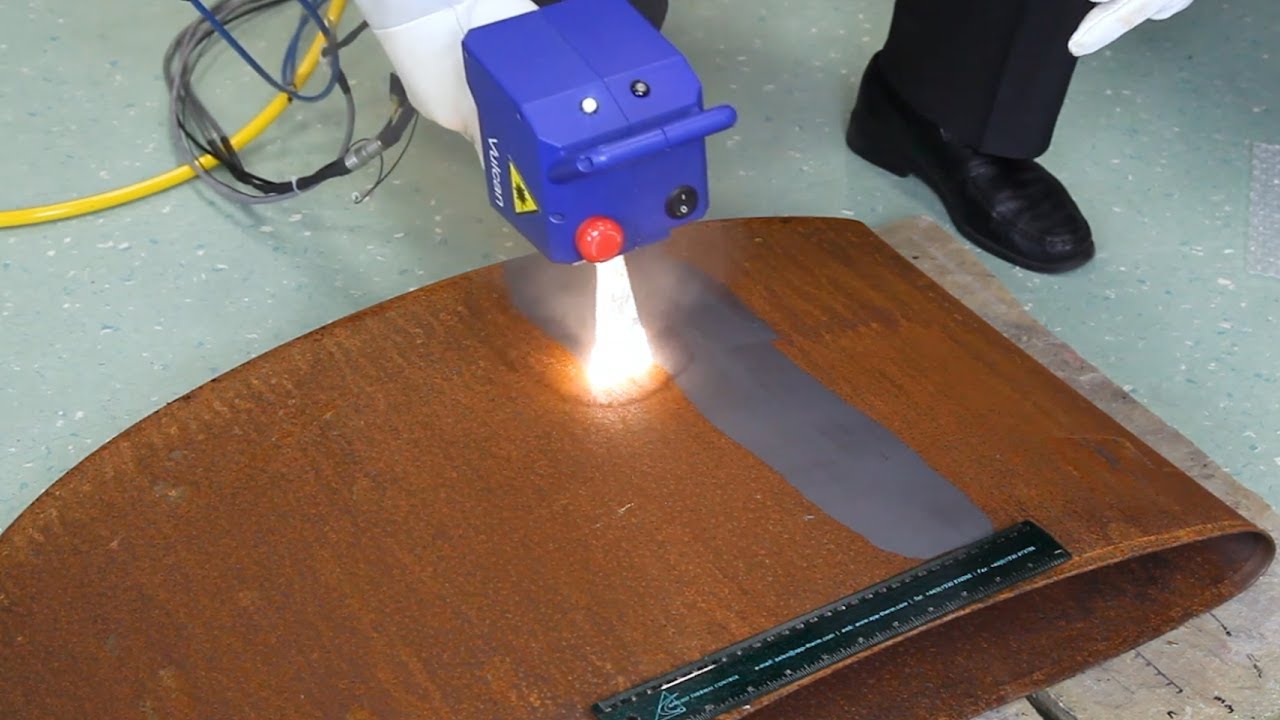

Laser rust removal technology represents a seismic shift in combating corrosion. By utilizing the precision and intensity of laser beams, this method effectively targets and eliminates rust without compromising the integrity of the metal beneath. This non-contact technique is rapid and exact, significantly minimizes waste production, and removes the need for harsh chemical agents. The result is a markedly more eco-friendly process, considerably reducing the ecological footprint associated with rust removal. Additionally, this technology is characterized by its conservative energy consumption, further underscoring its environmental benefits.

Comprehensive Advantages

Adopting laser technology in rust removal offers myriad benefits that extend well beyond its minimal environmental impact. Its unparalleled efficiency and precision translate into significant economic savings across various sectors by streamlining maintenance processes and reducing the need for costly repairs or replacements. The non-abrasive nature of the laser ensures that the structural integrity and aesthetic value of metal surfaces are preserved, thereby prolonging the lifespan of these materials. Moreover, the operational safety enhancements are profound, as workers are no longer exposed to the hazards associated with traditional rust removal methods, such as toxic chemicals and harmful dust.

Broad-Spectrum Applications

The utility of the laser for rust removal is evident across diverse industries, underscoring its versatility and effectiveness. In the automotive sector, it provides an invaluable tool for restoring classic vehicles, allowing for the removal of rust without damaging the original paint or metalwork. The aviation industry benefits from its precision and safety, ensuring that aircraft components remain corrosion-free while maintaining structural integrity. Additionally, in cultural heritage conservation, this technology offers a gentle yet effective means of restoring and preserving historical artifacts and monuments for future generations.

The Path Forward

As global initiatives increasingly focus on sustainable practices and green solutions, laser rust removal is a testament to the potential for technological innovation to align with environmental conservation. Its growing adoption reflects a broader commitment to preserving the natural world and enhancing operational efficiencies and safety in maintenance practices. As this technology advances and becomes more widely available, it is poised to revolutionize maintenance and restoration processes across the board, setting new environmental and efficiency standards for decades.

In detailing the process and benefits of laser rust removal, it’s crucial to acknowledge the synergy between technological innovation and environmental stewardship. This method starkly contrasts traditional rust removal techniques, which often rely on mechanical abrasion or chemical treatments. These conventional methods not only pose significant environmental risks through the emission of volatile organic compounds (VOCs) and the generation of hazardous waste but also present challenges in efficiency and effectiveness. Laser rust removal, however, provides a non-toxic, non-abrasive, and highly targeted approach, reducing the potential for environmental contamination and promoting a healthier workplace.

Moreover, the economic implications of adopting laser rust removal technology are profound. The initial investment in laser equipment is quickly offset by the reduction in ongoing costs associated with consumables, waste disposal, and health and safety measures required for traditional rust removal methods. Businesses leveraging this technology can also benefit from increased productivity, as laser rust removal can be performed more quickly and with less downtime for equipment maintenance. This efficiency gain and the potential for reduced regulatory compliance costs related to environmental and workplace safety standards make laser rust removal an economically attractive option for a wide range of applications.

Conclusion

The advent of laser rust removal technology represents a significant milestone in the ongoing battle against metal corrosion. By combining the principles of precision, efficiency, and sustainability, this innovative approach not only challenges but also surpasses the capabilities of traditional rust removal methods. It heralds a new era in which environmental responsibility and technological advancement go hand in hand, offering a brighter future for industries reliant on preserving and restoring metal assets. As this technology continues to evolve and its adoption widens, laser rust removal is set to redefine the landscape of maintenance and restoration, establishing new standards for environmental stewardship and operational excellence. In essence, the shift towards laser-based rust removal is not just a change in technique; it is a profound transformation in how we approach the preservation of our material heritage and the protection of our planet.