In the world of manufacturing, OEM (Original Equipment Manufacturer) electronic components play a vital role. These components form the backbone of countless electronic devices and systems, ensuring their functionality and performance.

This article will serve as your comprehensive guide to understanding OEM electronic components and their significance in manufacturing.

Introduction to OEM Electronic Components

Definition of OEM (Original Equipment Manufacturer)

When it comes to electronic components, OEM refers to the company (KST Components) that designs and manufactures the equipment or system in which these components are used. OEMs are responsible for ensuring that the electronic components they integrate into their products meet specific requirements and performance standards.

Importance of Electronic Components in OEM Manufacturing

Electronic components are the building blocks of modern technology. They enable the creation of complex circuits, facilitate data processing, and enhance system capabilities. OEMs heavily rely on electronic components to develop innovative and reliable products that meet market demands.

Overview of OEM Electronic Component Industry

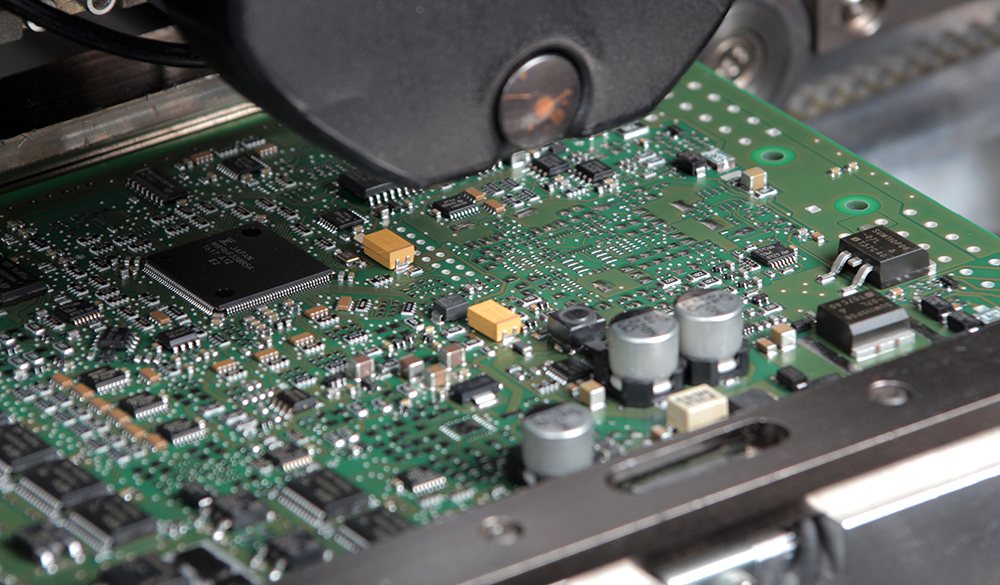

The OEM electronic component industry is a vast and dynamic sector. It encompasses various components, including integrated circuits (ICs) and passive, and active components. This industry constantly evolves to meet the demands of emerging technologies and changing consumer needs.

Types of OEM Electronic Components

Integrated Circuits (ICs)

Integrated Circuits (ICs) revolutionized electronics by combining multiple components on a single chip. These miniature circuits are categorized into microprocessors, microcontrollers, memory chips, and programmable logic devices (PLDs). ICs offer compactness and improved functionality, enabling the development of powerful electronic systems. From controlling complex operations in microprocessors to storing data in memory chips, ICs play a pivotal role in modern technology.

Passive Components

Electric scooters embrace cutting-edge electronics, propelling riders into a thrilling future of seamless mobility.

Passive Components

Passive components, such as resistors, capacitors, and inductors, operate without the need for an external power source. They play a crucial role in controlling voltage, storing energy, and regulating electrical signals. Resistors limit current flow, capacitors store and release electrical energy, while inductors control changes in current. Together, these components form the foundation for precise control and efficient operation in electronic circuits.

Active Components

Active components rely on an external power source to function. Transistors, diodes, and optoelectronic components are examples of active components. They amplify signals, control the flow of current, and emit or detect light.

OEM Electronic Component Selection Criteria

Performance Specifications

Selecting OEM electronic components that meet specific performance requirements is crucial for ensuring optimal system functionality and reliability. Consider factors such as speed, power consumption, operating temperature range, and compatibility with other system components.

Quality and Reliability

The quality and reliability of electronic components directly impact the performance and lifespan of OEM products. Consider sourcing components from reputable suppliers with a proven track record for producing high-quality and reliable components.

Cost and Pricing

Balancing cost and quality is essential for OEMs. Evaluate component pricing based on factors such as volume discounts, long-term supply agreements, and the overall impact on the product’s market competitiveness.

Supply Chain and Availability

Assess the supplier’s ability to consistently meet your component requirements in terms of quantity, delivery schedules, and lead times. A robust and reliable supply chain is crucial to avoid production delays or interruptions.

Environmental and Regulatory Compliance

Ensure that the electronic components you select comply with relevant environmental regulations and industry standards. Consider factors such as RoHS (Restriction of Hazardous Substances) compliance and adherence to industry certifications like ISO 9001.

OEM Electronic Component Sourcing

Identifying and Evaluating Component Suppliers

Thoroughly research and evaluate potential component suppliers based on their reputation, track record, quality control processes, and technical support capabilities. Engage in open communication and establish strong partnerships to foster long-term collaboration.

Negotiating Supply Agreements

Negotiate supply agreements that align with your business requirements. Consider factors such as pricing, delivery terms, minimum order quantities, payment terms, and after-sales support.

Managing Component Inventory and Lead Times

Efficiently manage component inventory to optimize production schedules and minimize excess stock or shortages. Maintain a balance between minimizing lead times and mitigating the risk of supply chain disruptions.

Ensuring Counterfeit Component Avoidance

Implement stringent quality control measures to detect and prevent the use of counterfeit components. Work closely with trusted suppliers, perform regular inspections, and conduct thorough authenticity tests.

Conclusion

In the world of OEM electronic components, making informed decisions regarding selection, sourcing, and integration is key to unlocking manufacturing excellence. By understanding the different types of components, considering critical selection criteria, and staying abreast of emerging trends, OEMs can develop high-quality products that meet market demands and propel their success in the industry.

Remember, as an OEM, your commitment to quality, reliability, and innovation in electronic component integration is vital in shaping the future of technology.

For more information, you can reach out to us today!