Aluminium die casting is an economical and reliable process for producing small to medium-sized metal parts. This article will provide you with more information about aluminium die casting so that you can determine if it’s right for your application.

About aluminium die casting

Aluminium die casting happens when molten aluminium alloy flows into a mound, which then cools and hardens around its desired shape. This happens because it does not have excess air bubbles inside where they are formed. Each casing must maintain perfect tolerance throughout the process as it happens in the aluminium die casting company in Malaysia.

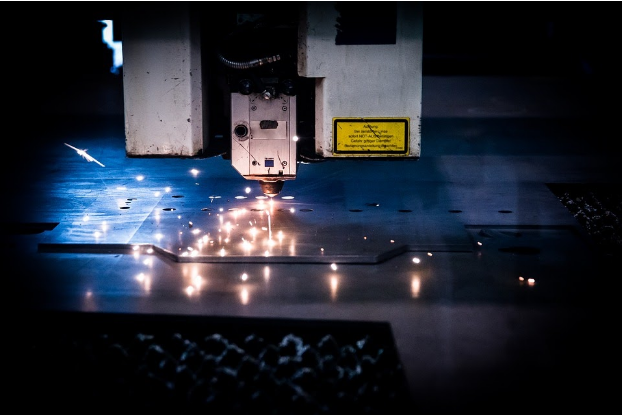

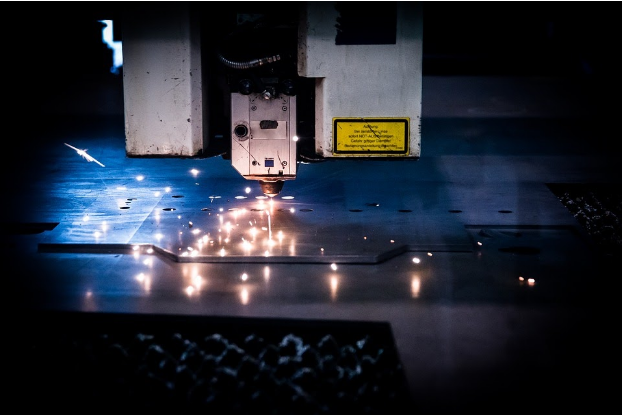

How does aluminium die casting happen?

People who work in the aluminium industry spend their days watching molten metal flow into a mold, then cool and solidify. They use complex control panels to oversee the process while they wait for hours on end until every last bit of liquid has congealed.

What materials are used for die casting?

The aluminium alloy that you’re going to find the most common is a molten salt aluminium alloy because it’s very low in cost and it melts at room temperature. The second one would be an electric arc furnace, but this type of metal can only produce high-purity alloys for aerospace applications using more expensive equipment like vacuum induction furnaces or some other method with strict quality control measures.

Advantages of die casting

- Aluminium die casting is one of the more affordable methods for manufacturing cast components. This process can be completed in a matter of days, and since aluminium costs less than other metals as well, this method has become very popular with manufacturers everywhere

- The production of near-net-shape castings is an economical and time-saving method that allows for the elimination or reduction of secondary machining. These benefits are achieved because one can eliminate internal features in a component by casting it from aluminium dies, which saves both money and manufacturing costs.

- Aluminium is an excellent material for die casting because it has high conductivity and channels heat very well.

- Aluminium contributes to many positive features that make it an ideal choice for any project requiring customization or where cost efficiency is crucial because it can be produced at such a large scale with so few defects relative to other metals like steel which would require more time consuming manual labor methods during manufacturing processes

- Aluminium die casting is less expensive than other methods of manufacturing cast components such as sand and permanent mold processes. Besides being cost-effective, this process also boasts an impressive production rate that’s typically much higher than its competitors.

- The castings are hermetically sealed by liquid aluminium alloys, which is a great advantage because they’re extremely durable and can withstand rust.

- The lightweight material is corrosion-resistant which means you can use it for years without worry about metal fatigue or breakage due to weathering.

- Aluminium die casting can produce several items at one time without having any overlap in the process and speedier results for lead-time since it only requires one production cycle instead of two or more separate ones like most others do.

- Aluminium die casting is great because it produces a reliable product that can be recycled. so the material doesn’t need to go straight into scrap metal after one use.