Why Efficient Pipe Replacement Matters

Pipe replacement is crucial for maintaining well-being and sustainability in urban and rural communities. Water distribution networks, sewer lines, and underground utilities age rapidly due to environmental stresses, heavy usage, and poor weather conditions. Delays and inefficiencies can lead to catastrophic failures like leaks, sinkholes, road collapses, or sewage overflows. Emergency repairs can outpace planned, efficient replacement costs financially and in terms of community disruption.

That’s why contractors and utility repair teams increasingly use advanced equipment like pipe puller tool kits to streamline the process. These kits allow teams to work faster, with less excavation and damage to aboveground property, reducing inconvenience for residents and local businesses. Choosing efficient, minimal-disruption methods to carry out this massive work is not just about saving money—it’s about protecting daily life and safeguarding water quality for generations to come.

Core Challenges in Pipe Replacement

Underground pipeline replacement is a complex task due to the buried nature of most pipes, which can disrupt traffic, disrupt businesses, or damage established gardens and trees. Modern cities often have overlapping utilities, making the digging process risky and posing safety hazards. The unpredictable nature of underground environments, such as changes in plans or soil shifts, can also complicate the process. Skilled teams must be prepared for surprises and balance a careful approach with the need for quick and cost-effective completion. Modern pipe replacement crews require adaptability, experience, and technical solutions.

Must-Have Tools for the Job

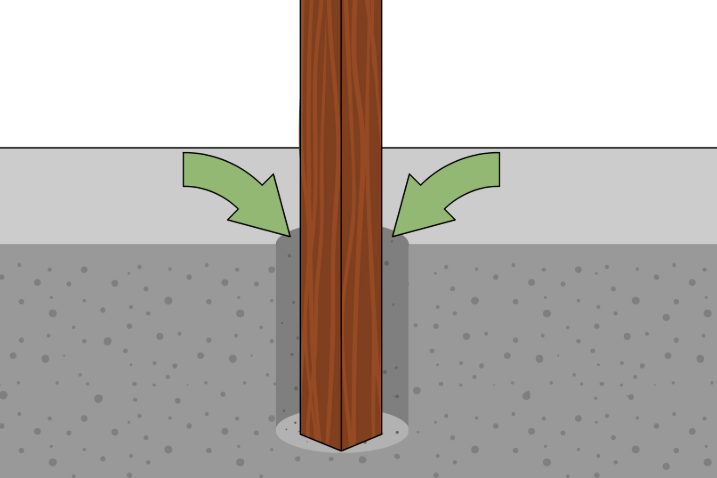

Pipe replacement projects have evolved from traditional hand tools to more sophisticated tools like inspection cameras, leak detection equipment, high-torque pipe wrenches, hydraulic cutters, fiber-optic pipe inspection cameras, advanced leak detection meters, trenchless pipe pullers, and protective clothing. These tools help identify blockages, corrosion, and collapse points before digging, influencing the chosen tactics. Leak detection equipment allows operators to trace water loss sources, while high-torque wrenches and hydraulic cutters facilitate quick removal and installation. Fiber-optic cameras relay live images from sealed pipes, and trenchless pipe pullers allow for minimally invasive work.

Innovations in Pipe Replacement Technology

The pipe replacement industry has seen significant advancements in recent years, with trenchless technology such as pipe bursting, slip lining, and cured-in-place pipe (CIPP) systems revolutionizing project management. These methods reduce the need for street disruptions, landscaping work, and business district closures. They save municipalities money in labor and materials and avoid costs from traffic delays and disruptions. Even small towns now have access to these technologies, allowing proactive maintenance instead of expensive emergency repairs. Future research and development promise faster, greener solutions, paving the way for more innovative solutions in the pipe replacement industry.

Safety Considerations During Replacement

Underground utilities are exposed to hazards, including cave-ins and hazardous substances like contaminated groundwater, asbestos, and methane. Safety protocols are crucial for workers, starting with thorough planning, risk assessments, and clear site markings. High-visibility clothing and protected work zones ensure safety, while lockout/tagout systems prevent accidental utility line activation. Regular training ensures best practices are never forgotten and teams know how to respond to changing conditions or emergencies. Safety-driven processes ensure that every team member returns home healthy after the job is completed.

Training and Skills for Field Teams

Pipe replacement projects require a combination of physical skill, technical knowledge, and quick decision-making. Organizations now require certifications in both traditional plumbing and modern trenchless methods. Ongoing professional development through trade schools, field training, and manufacturer workshops keeps skills current. Teams trained in inspection cameras, pipe pullers, and trenchless installation kits are less likely to encounter mistakes or delays. Strong communication and leadership skills foster teamwork and quick problem-solving. As pipe replacement becomes more complex, investing in training results in faster, safer, and more reliable infrastructure upgrades.