Welcome to your one-stop guide about bearings! Whether you’re an experienced engineer, a DIY fan, or just curious about how machines work, you’re in the right spot. Bearings are key parts that help machines run smoothly, whether small or large.

There are many types of bearings, so picking the right one can be confusing. This guide will clearly explain the main types, where they’re used, and important tips to help you choose the best bearing for your needs. Let’s begin!

What Are Bearings and Why Do They Matter?

Bearings are important parts in machines that help reduce friction between moving parts. They make it easier for parts to move smoothly and in the right direction while supporting the machine’s weight or force.

Think of bearings as smooth surfaces or rolling parts—like tiny balls or cylinders—that sit between moving machine parts. Instead of rubbing directly against each other, the parts move with the help of these smooth or rolling elements, which greatly reduces wear and tear.

Why Bearings Matter:

Bearings are essential because they:

- Reduce Friction – Help parts move more easily and with less energy.

- Support Loads – Keep machines stable and able to carry weight.

- Control Motion – Guide parts to move exactly how they’re supposed to.

- Increase Lifespan – Make machines last longer and run more efficiently.

Bearings ensure smooth, quiet, and reliable machine operation, from home blenders to factory equipment.

Main Types of Bearings and Their Uses

Bearings reduce friction between moving parts and keep machines running smoothly. Different types fit various loads, speeds, and space needs.

- Ball Bearings

Ball bearings use small balls to reduce friction between moving parts. They are ideal for high-speed applications and can handle light to medium loads. Common uses include fans, motors, skateboards, and hard drives. However, they are not suitable for very heavy loads.

- Roller Bearings

Roller bearings use small cylinders instead of balls to reduce friction. They support heavier loads and commonly operate in heavy machines, gearboxes, and conveyor belts. However, they don’t perform well at high speeds or under strong side forces.

- Needle Roller Bearings

Have long, thin rollers. Fit in tight spaces and handle heavy side-to-side loads. Used in car gearboxes and small engines. Not good for loads from the shaft’s end.

- Tapered Roller Bearings

Have cone-shaped rollers. Handle loads from the side and end. Used in car wheels, truck axles, and heavy machinery. Need careful installation.

- Spherical Roller Bearings

Spherical roller bearings use barrel-shaped rollers that automatically adjust to slight shaft misalignment. They support heavy loads and operate in wind turbines and heavy industrial machines. However, they are larger and heavier than other types.

- Thrust Bearings

Made to handle force in one direction (axial).

- Thrust Ball Bearings: Ideal for light loads and low-speed applications, such as in chairs.

- Thrust Roller Bearings: For heavier loads in transmissions.

- Plain Bearings (Bushings)

Smooth surfaces instead of balls or rollers. Used in engines and hinges. Simple, cheap, good for heavy loads, but creates more friction and wears faster.

- Magnetic Bearings

Magnetic bearings use magnets to suspend parts without contact, eliminating friction. They’re ideal for high-speed machines like turbines and aerospace systems, but are costly and require complex control systems.

How to Choose the Right Bearing for Your Application

Selecting the right bearing ensures your machinery runs efficiently and lasts longer. The best choice depends on these key factors:

- Load Type

- Radial Loads (side pressure): Use deep groove ball or cylindrical roller bearings.

- Axial Loads (end pressure): Use thrust ball or tapered roller bearings.

- Combined Loads: Use angular contact ball or spherical roller bearings.

- Speed

- High Speed: Use low-friction bearings like precision ball bearings.

- Low Speed: Use stronger load-bearing types like roller bearings.

- Environment

- High Temperature: Choose heat-resistant materials/lubricants.

- Dirty or Contaminated Areas: Use sealed or shielded bearings.

- Moisture/Corrosive Conditions: Use stainless steel or coated bearings.

- Maintenance

- Limited Maintenance Access: Use maintenance-free/self-lubricating bearings.

- Routine Maintenance Available: Standard bearings may offer a longer life if well-maintained.

- Life Span & Reliability

- Choose bearings with suitable dynamic load ratings.

- High-reliability bearings are essential for critical applications.

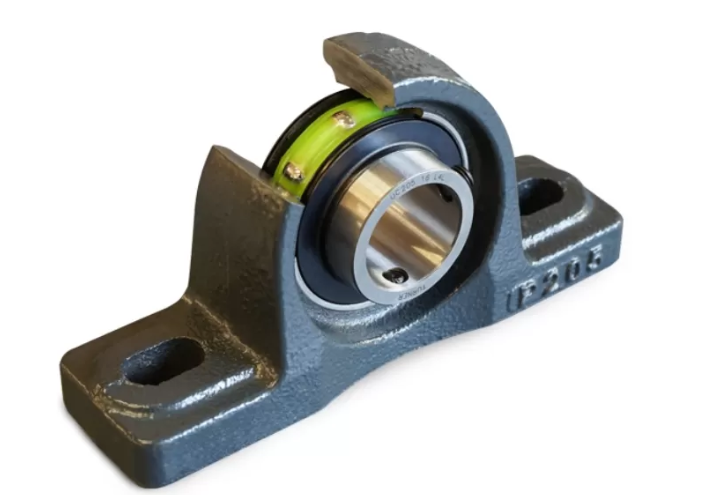

- Space & Mounting

- Limited Space: Use compact types like needle or thin-section bearings.

- Ease of Installation: Some come with flanges or housings for simpler mounting.

- Cost

- Weigh initial cost vs. long-term value.

- For essential systems, higher-quality bearings may reduce future downtime and costs.

Always choose bearings that fit your machine’s load, speed, environment, and maintenance needs to ensure the best performance.

Common Bearing Materials

- Steel Bearings

-

-

- Chrome Steel: Very hard, long-lasting, affordable, but prone to rust and not good at high heat. Used in cars, industrial machines, and aerospace.

- Stainless Steel: Resists rust and heat, ideal for humid or marine use, but softer and pricier; used in food, medical, and marine fields.

-

- Ceramic Bearings

Made from silicon nitride or zirconia. Very hard, wear-resistant, corrosion and heat-resistant, low friction, and non-magnetic. However, brittle, costly, and hard to repair. Used in high-speed spindles, aerospace, semiconductors, and medical devices.

- Bronze Bearings

Copper-tin alloys, sometimes with lead. Good wear and corrosion resistance, often self-lubricating, good heat transfer. Softer than steel, higher friction, not for high-speed use. Used in heavy machinery, bushings, and marine applications.

- Polymer/Plastic Bearings

These bearings, made from Teflon and Nylon, are lightweight, corrosion-resistant, and reduce friction and noise. They handle light loads and low heat but may deform over time. They’re commonly used in food processing, chemical plants, electric motors, and dirty or low-lubrication environments.

Bearing Maintenance and Lifespan Tips

Maintaining bearings properly is crucial to ensure their longevity and optimal performance. Here are essential tips to help you achieve this:

- Handle and Store Carefully: Store bearings in original packaging, clean, dry, and horizontal. Handle carefully to avoid damage or contamination.

- Install Properly: Inspect shafts and housings before mounting. Use the right tools and methods to avoid damaging the bearing during installation.

- Maintain Cleanliness: Clean bearings before installation and protect them from dirt during operation. Regularly check for contamination or wear.

- Lubricate Correctly: Use the appropriate lubricant for your bearing and conditions. Apply the right amount—too much or too little can cause problems. Monitor lubrication regularly.

- Inspect and Monitor Regularly: Check for signs like wear, unusual noise, shaking, or temperature changes. Use special tools like vibration analyzers or heat cameras to find problems early.

- Follow a Maintenance Plan: Schedule regular inspections based on bearing type and usage. Use predictive maintenance tools to catch issues early and prevent unexpected failures.

Following these steps helps extend bearing life, reduce downtime, and keep machinery running smoothly.

Conclusion: Choosing the Right Type of Bearing

Bearings are essential for smooth, quiet, and efficient machine operation in both small devices and large industrial systems. Choosing the right type, based on load, speed, and conditions, is key to ensuring optimal performance and durability.

Understanding the function and best use of ball, roller, needle, tapered, spherical, thrust, plain, and magnetic bearings helps you match the right type to your application. By considering factors like load direction, speed, environment, maintenance needs, and material properties, you can make informed choices that improve reliability and reduce downtime.

Use this guide as your go-to resource to confidently select the best bearing for your project, ensuring optimal function, longer machine life, and greater efficiency.